That T-shirt you’re wearing—do you know how much water was used to make it?

How much fuel was expended to ship it?

How many ounces of scraps were cast aside from the trimmings?

Consider the classic white t-shirt.

Annually, 2 billion t-shirts are sold and bought globally, making it one of the most common garments in the world.

But how and where is the average t-shirt made, and what’s its environmental impact?

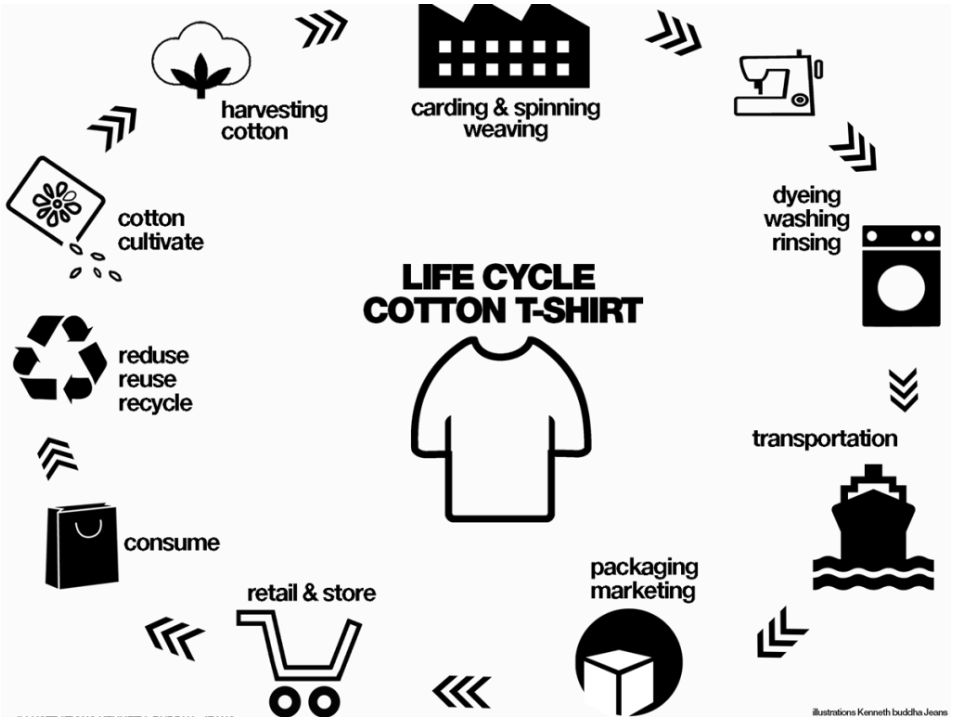

The life-cycle of a t-shirt

Let’s consider the life cycle of a t-shirt. A ‘Life Cycle’ as defined by the International Organization of Standardizations (ISO) is a methodology to assess the environmental impacts of a process, service or product.

It’s not just, ‘you buy it, you wear it, you throw it away,’ which defines, perhaps, a t-shirt’s life in your wardrobe; let’s think about the full scale impacts of a t-shirt on the planet.

Cotton Farming for Textile Production

The environmental cost of cotton cultivation is a significant concern.

The use of pesticides and fertilizers in cotton farming has led to soil degradation, water pollution, and loss of biodiversity.

Additionally, cotton farming requires large amounts of water, which can lead to water scarcity in areas where water resources are limited.

The production of cotton also contributes to greenhouse gas emissions, as energy is required for irrigation, transportation, and processing.

Most t-shirts are made from cotton, which is grown in 80 countries by 25 million farmers who produced a total of 25.9 millions tonnes of fiber between 2018 and 2019. Conventional cotton farming consumes 6% of the world’s pesticides even though it only uses 2.4% of the world’s land.

These chemicals control pests like the pink bollworm, but they can also poison other wildlife and people. Farmers tend to use large amounts of synthetic fertilizer to maximize the amount of cotton they grow, which can degrade soil and pollute rivers.

More than 70% of global cotton production comes from irrigated farms (Irrigated farms are agricultural lands that receive water through artificial means, such as canals, pipes, or sprinklers) and it takes one-and-a-half Olympic swimming pools of water to grow one tonne of cotton.

A single t-shirt could have used 7,000 liters of water just to grow the cotton it’s made from.

Finishing touches

Once the cotton is grown and harvested, the production phase begins.

Spinning, knitting, wet process, bleaching, dyeing, confection, cutting and sewing.

Aside from the vast amount of water and energy all of these processes use, commercial dyes and bleaches are harmful pollutants that can ultimately contaminate groundwater.

The environmental cost associated with the dyeing process of textiles is a matter of great concern.

The use of synthetic dyes and chemicals in the process leads to the release of harmful pollutants into the environment, causing significant damage to ecosystems and human health.

The depletion of natural resources, such as water and energy, is also a major issue.

Transportation

After the t-shirt is made, it needs to be transported.

If you look in your closest you’ll likely find a variety of countries of origin on your clothing tags. Studies have found that cargo trucks alone account for 1.15 pounds per mile of carbon emissions into the atmosphere.

Planes, ships and trains use much more.

The transportation of textiles incurs a significant environmental cost.

The production and distribution of textiles require the use of fossil fuels, which contribute to greenhouse gas emissions and air pollution.

Additionally, the transportation of textiles often involves long distances and multiple modes of transportation, further increasing the environmental impact.

Retail

The next phase is retail, which may seem like the least harmful phase but… think again.

The biggest environmental drain your clothing causes comes from the repeated washing and drying we all do to keep our clothes clean.

In fact, the environmental impact of laundering that t-shirt for its life cycle (about 75 times) creates 17 times more CO2 emissions than the entire production process from cotton seed to retail store, two thirds of which is from using a conventional tumble dryer.

Disposal

The ultimate phase in the life cycle of a t-shirt is its disposal, which regrettably entails a considerable amount of carbon emissions and environmental contamination.

However, this stage also presents an opportunity for exerting some degree of influence.

‘’How can I reduce my environmental footprint?’’

In order to minimize your environmental impact through your clothing choices, there are several steps you can take:

Firstly, consider purchasing clothing made from sustainable materials such as organic cotton or recycled polyester.

Secondly, opt for high-quality garments that will last longer and require fewer replacements.

Thirdly, avoid fast fashion and instead invest in timeless pieces that can be worn for years to come.

Additionally, consider donating or recycling clothing that is no longer needed rather than throwing it away.

Lastly, wash your clothes in cold water and hang dry them to reduce energy consumption.

By implementing these practices, you can significantly reduce your environmental footprint through your clothing choices.

#textile #pollution #tshirt #environmental #footprint